The Poplock Impact Bit Socket Set features a patented two-layer steel design that combines an ultra-hard HAT-08 tip with a tough Cr-Mo 440 shock-absorbing body for 10× longer life and consistent torque performance.

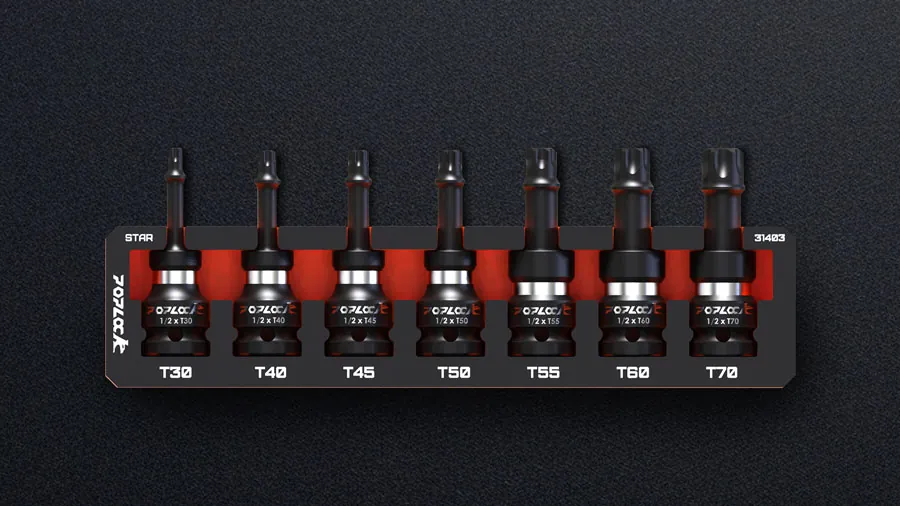

Available in 7- or 5-piece sets (T30–T70).

Buy now on

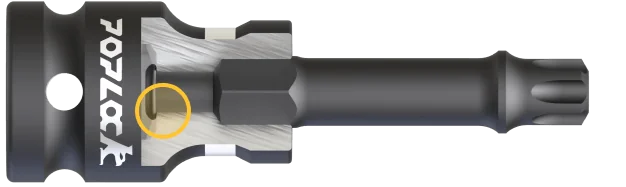

Traditional impact sockets often fail at the joint between the bit and the socket body. POPLock’s patented Mushroom Head Press system redefines impact socket construction.

The Mushroom Press creates an interference fit that gets stronger under load. As torque increases, the interlocking joint tightens instead of loosening, the exact opposite of threaded or pinned connections that work loose over time.

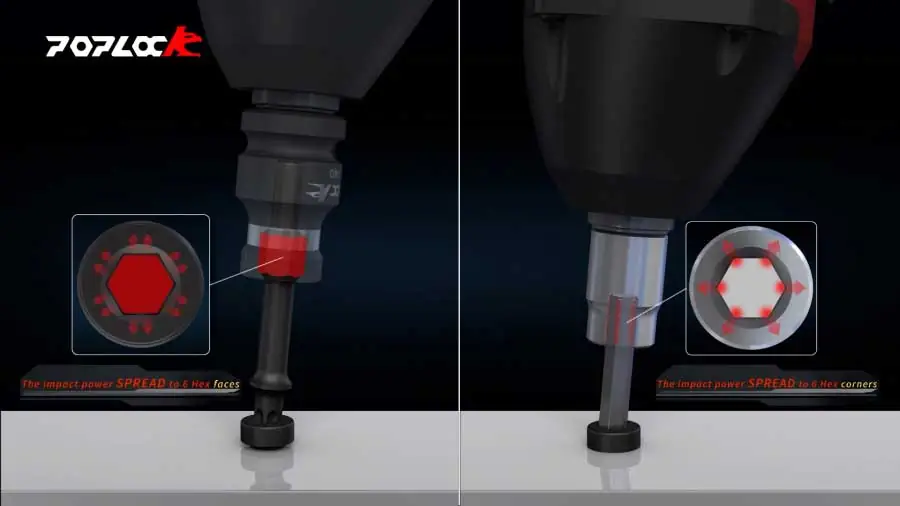

Standard impact sockets use one type of steel to balance hardness and flexibility, but that compromise fails under real impact stress. A material hard enough to resist wear becomes brittle, while one soft enough to absorb shock quickly deforms.

Poplock solves this with a dual-alloy design: an ultra-hard HAT-08 tip that keeps its shape and a tough Cr-Mo 440 body that flexes to handle repeated impact. Each material performs where it’s strongest, giving the tool lasting strength and resilience.

Traditional sockets rely on interference fits, welds, or pins that introduce weak points and eventually loosen under impact.

Poplock’s patented Mushroom Press Fit uses a precision forming process to create a mushroom-shaped interlock that locks the bit and socket together across a wide surface area. This design spreads stress evenly, preventing cracks and separation.

During use, repeated impact and torque generate localized heat and pressure inside the interlock zone. This triggers molecular-level diffusion between the two metals, creating a gradual bond that becomes tighter with time — the exact opposite of traditional joints that wear loose.

Unlike traditional sockets that allow small misalignments and wasted torque, Poplock’s 0.02 mm precision keeps every bit perfectly centered.

This exact alignment delivers full power to the fastener with zero wobble or vibration, reduces tool wear, and maintains stability under heavy load.

Unlike standard hex shafts that concentrate stress at their corners, Poplock’s round torsion shaft distributes force evenly through 360°.

This design absorbs impact energy, reduces vibration, and protects both the bit and fastener for smoother, longer-lasting performance.

Compared to traditional 2 pcs bit sockets or conventional 1 pc impact socket designs in identical applications.

Tested performance before measurable wear in heavy-duty industrial applications

Professional mechanic feedback productivity gains and reduced tool replacement costs

Poplock underwent extensive field and laboratory testing against leading star bit socket sets. Continuous high-torque operation, endurance cycling, and destructive testing proved the Poplock design delivers over 10× longer service life and 10,000+ fastening cycles with zero structural failures.

Field-tested by mechanics and industrial users, Poplock achieved 98% satisfaction for torque accuracy, tool stability, and reduced replacement cost. The technology delivers measurable ROI through fewer replacements, higher work quality, and smoother, more efficient fastening.

Available in 7 or 5-piece sets, covering T30 to T70 sizes, this tool is perfect for professional or DIY tasks across various applications.

| 7-Piece Star Impact Driver Bit Set Specs | ||||||

|---|---|---|---|---|---|---|

| Model No. 31403 | Sizes | Total Length | Description | |||

|

| T30 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T40 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T45 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T50 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T55 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T60 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T70 | 75mm | 1/2" Drive STAR Impact Bit Socket set | |||

| 5-Piece Star Impact Driver Bit Set Specs | ||||||

|---|---|---|---|---|---|---|

| Model No. 31406 | Sizes | Total Length | Description | |||

|

| T30 | 150mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T40 | 150mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T45 | 150mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T50 | 150mm | 1/2" Drive STAR Impact Bit Socket set | |||

|

| T55 | 150mm | 1/2" Drive STAR Impact Bit Socket set | |||

Keeping these in my toolbox because ford loves to throw in random T bit bolts and these are crafted nicely.

Read MoreWhat a great set! Im sure there are a lot of different uses for these but for me its an amazing find for me as a Jeep Wrangler owner. I am always in need of T40/T45 and more while off-roading or Jeeping. This set has all the sizes I always need to carry with me. I can take off my Jeep roof and do tons of other things with this set. The box is cool to keep them in but they also come with a free socket holder for the tool box that keeps them all together and safe from rolling around. The sockets are made very well, tough, strong material even when using them on an air ratchet. They have held up great form me and I can tell they will last a long time. I also love the chrome ring on black that they chose for the color scheme. They are good-looking and well made T sockets!

Read MoreIt seems like everything we purchase lately comes with these stars sockets now. We didn’t have a set like this before, and wow, has it come in handy lots since we got this. This set is well made, and a very nice addition to our tool set.

Read MoreWe are committed to supporting our customers and ensuring your satisfaction with our innovative hand tools. If you have any questions, concerns, or need further assistance, our dedicated support team is here to help. Please visit our support page for more information or to get in touch with us.

Support

We offer two primary sets:

Item No. 31403 — 7-Piece (T30–T70), 75 mm Length Each

Sizes: T30, T40, T45, T50, T55, T60, T70

Total length of 75 mm (approximately 3 inches)

Ideal for standard-depth fastener access

Item No. 31406 — 5-Piece (T30–T55), 150 mm Length Each

Sizes: T30, T40, T45, T50, T55

Extra-long length of 150 mm (approximately 6 inches)

Perfect for deeper or recessed fasteners

Both sets utilize our patented two-piece Poplock impact design, engineered specifically for Torx (6-lobed) fasteners.

These impact sockets employ a patented 2‑layer design with a “Marshroom Press” locking method, permanently bonding the bit shaft to the socket so that no individual bit replacements are necessary. The bit material (HAT‑08) is hardened to HRC 56–60 to handle high impact forces, while the socket material (Cr‑Mo 440) is hardened to HRC 46–52 for exceptional toughness. A round shaft torsion body helps distribute torque evenly, reducing breakage. Full contact on each hex side also minimizes wear. This structure delivers higher torque capacity, an extended service life, and more reliability than typical 1‑piece or standard 2‑piece designs.

The Poplock customize own 6‑lobe (Torx) tip is precisely CNC machined for a snug fit, which reduces the chance of the bit slipping or stripping the fastener. This design also improves torque transfer to the fastener head, lowers the risk of cam‑out, and helps protect the screw head from damage or rounding.

Yes. The industrial‑grade steels and Marshroom Press–locked 2‑layer construction excel in demanding jobs. They’re ideal for automotive work—covering engines, transmissions, and suspensions—as well as construction and manufacturing tasks that involve repetitive, high‑torque fastening. Their durability under continuous impacts makes them well‑suited for both professional and high‑end DIY applications.

Absolutely. They are designed with a 1/2‑inch drive, making them compatible with a wide range of pneumatic, electric, and cordless impact wrenches. The torsion zone in the round shaft helps dissipate the repeated strikes from impact tools, ensuring steady performance and protecting both the sockets and the fasteners.

The round shaft torsion body is engineered to absorb and spread out impact energy along the neck of the bit. By not focusing all the force at the tip or the socket edges, the design cuts down on breakage, extends the life of the socket, and ensures a stable grip during high‑torque operations. Traditional designs often concentrate stress in fewer areas, increasing the likelihood of sudden failure.

Yes. Each socket is laser‑etched with its Torx size for quick identification. We also use EVA foam packaging for both Item No. 31403 and Item No. 31406, and each size is printed on the foam to help you easily locate the right socket. Additionally, the consistent lengths—75 mm for Item No. 31403 and 150 mm for Item No. 31406—make it simple to distinguish one set from the other on your workbench or in your toolbox.

Simple maintenance can help maximize service life. Always wipe the sockets clean after use to remove debris or metal shavings, and keep them dry to prevent rust. A light coating of rust‑inhibiting oil before storage is advisable, and storing them in a clean, dry place will reduce accidental damage or corrosion.

Yes. The proprietary steels, coupled with the Marshroom Press method, are designed to endure ongoing high‑torque usage without compromising performance. The torsion zone relieves stress on both the socket and the fastener, making these sets perfect for industrial or professional environments that require constant impact work.

No. Because of the permanent Marshroom Press locking technique, the bit shaft and socket are fused together. This integrated approach provides maximum strength and durability, but the bit portion itself is not replaceable as an individual component.

Yes. We include a standard 3‑year warranty, and product registration qualifies you for a free lifetime warranty. This level of coverage shows our confidence in the toughness and lasting performance of our patented impact bit socket sets.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |