If you look at the catalog of any hardware store you’ll see a wide variety of pry bars, nail pullers, crowbars and wrecking bars of all different sizes, some flat, some rounded, and in 2025 we’re seeing increasing demand for index head pry bars. Let’s have a look at what the difference is between them, or are these all just different names for the same thing?

What’s in the name: Pry bars, nail pullers & wrecking bars

The name looks pretty self explanatory – bars for prying things, bars for pulling nails, and bars for wrecking things. (It gets more difficult when you try to explain ‘crowbar.’) Any bar with an angled, flattened end is going to be good for prying things open that you want to keep intact (pry bar) or prying things apart that you’re intent on breaking (wrecking bar).

Pry bars are also used for pulling nails, with a notch in the end of the flat to go around and under the head of the nail. It seems that pry bars, no matter what name they go by, are generally considered to be one of the essential hand tools, along with hammers, screwdrivers, saws, and socket sets.

Are crowbars named after crows?

Nobody knows, but a crowbar does have a ‘beak’ shape and the origins of the name date back as far as 1400, when they were just called ‘crows’ – for over 600 years they’ve been used for removing nails, prying apart boards, and generally breaking things. Crows (as tools) are mentioned by Shakespeare in the play Romeo and Juliet, so they have a long and illustrious history.

The curved, flattened ends of crowbars do make it seem logical that they are named after crows, as birds have a tendency to pick things apart with their beaks. The crow is a highly intelligent foraging bird, commonly found in Europe where the name crowbar seems to have come from. Observation of crows using their beaks to pry open rotten wood looking for grubs is a possible inspiration for the name.

Pry bars, nail pullers, wrecking bars, crowbars & lever classes…

We’re looking at a bar with modified ends that’s used for prying. Pry bars, nail pullers, wrecking bars and crowbars all come under the general classification of levers. Levers are defined by classes, and perhaps that’s where we should look next in exploring this group of extremely useful hand tools.

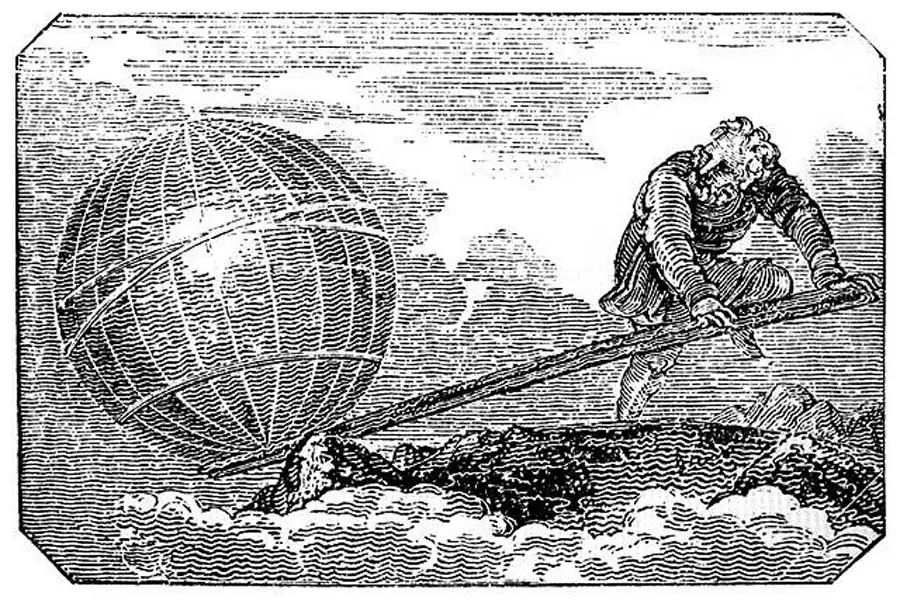

Levers are, of course, very useful indeed. The ancient Greek inventor Archimedes suggested that if you have a long enough lever and something to stand on that is far enough away you could move the world with nothing more than your human body weight. It turns out that it would have to be a very long lever to move the Earth – over 100,000,000 light years – which is not your average crowbar!

What are the three classes of levers?

| Class | Description | Examples |

| I | Fulcrum between load and effort | Pry bars, crowbars, wrecking bars, nail pullers |

| II | Load between effort and fulcrum | Wheelbarrows, bottle openers, wrenches |

| III | Effort between fulcrum and load | Human bicep, swing shovel, fishing rod |

What turns a lever into a pry bar?

The standard Class I lever has been modified over the centuries to turn it into a pry bar, and we’ve already considered that the distinction between pry bar, wrecking bar and nail puller are more about how we use this modified lever than about the fundamental design. However, when we look at the pry bars that are being made today we can see that although there are many similarities, there are some subtle, and not so subtle, differences in design that do have an impact on the intended use.

What are pry bars made of?

Carbon steel is the most commonly used material for pry bars, but a range of steel alloys and coating systems are used depending on how flexible and how corrosion resistant the pry bar needs to be. In the past pry bars were often made of iron, but the availability of more corrosion resistant steel alloys has supplanted the use of iron today.

How does cross-sectional shape influence pry bar design?

The cross-sectional shape of a pry bar can be used to increase stiffness, and some cast crowbars and wrecking bars in particular have an I-beam centre section. Round, oval and hexagonal shaft cross-sections are used across designs for pry bars, wrecking bars and nail pullers on the market today.

- I-beams for strength

- Flat bars are more springy

Some pry bars have a flatter sectional profile, this is more commonly found in budget pry bars and nail pullers, as it significantly reduces the stiffness of the bar, but it can work adequately for nail extraction. Flat bars are also uncomfortable to handle compared to round or elliptical bars, which are the most comfortable in the hand.

How do the shapes of pry bar ends affect their use?

This is one area where design changes in the way a pry bar, crowbar or wrecking bar can be used. The shape of the ends, more specifically the head and foot, of the pry bar is better suited to some tasks than others, and you’ll usually find that pry bars will have very different shapes at each end that are better used for different tasks.

Goose neck crowbars, pinch bars & alignment bars

The standard crowbar design is a reverse curve at one end (a ‘goose neck’) with a notch in the middle for nail pulling and a gentle curve to a wedged chisel tip at the other for levering and prying under nailed boards. Clawed bars are a standard for pulling flush nails. Pinch bars, otherwise known as alignment bars, tend to be longer, stronger and straighter than other pry bars, and are used for positioning heavy objects and tasks like lining up bolt holes in girders.

Rolling head crowbars

‘Rolling head’ crowbars have a short 90 degree angle head that is used to get increased leverage when separating objects that are in confined spaces, like ball joints in car suspension, or for holding parts in position when assembling engine components. The angle and length of the head of the pry bar has a significant impact on the leverage that can be exerted in any specific circumstances.

What are the limitations of crowbars & pry bars?

A limitation of standard crowbars and pry bars is that they have fixed angles and shapes which you can’t change, so although you have a different head at each end, a single pry bar won’t always be the right one for the job in front of you. This is why pry bar sets are popular, containing an assortment of pry bars of different sizes and configurations, and is also why we see increasing use of indexing pry bars, where you can adjust and lock the head angle.

How do indexing pry bars work?

An indexing pry bar has an adjustable joint between the head and the shaft, enabling the head to be rotated and set at a different angle to the shaft depending on the requirements of the job. This enables an indexing pry bar to be used as a crowbar, nail puller or rolling head crowbar, the only limitation being the size of the pry bar itself.

A set of indexing pry bars of different sizes becomes extremely useful as by changing the head angle to the pry bar shaft you can easily expand the utility of your pry bars without needing a large number of different specific types.

Poplock specializes in high quality indexing pry bars, and our indexing pry bar sets come in sizes and configurations that are designed to fulfil the widest possible range of uses. If this explanation of the history and uses of pry bars, nail pullers and crowbars has got you thinking about getting a new one, please take a look at what we have to offer, we’re sure you’ll be impressed!