The best impact star bit socket set in the world seems like a big claim to make until you see why Poplock was able to patent our revolutionary impact socket design. Poplock impact star bit sockets demonstrate our expert approach to fixing the issues that other impact socket sets have with brittle failure, deformation and shattering under repeated load.

How did Poplock make the best impact star bit socket set in the world?

There’s no point in trying to make a better star bit socket set unless you start by working out what goes wrong with the existing, standard, star bit sockets and Torx socket sets. We started the journey of building the best impact star bit socket set by going into analysis mode. We looked at how star bit sockets fail under repeated impact loading and identified the key weaknesses of existing designs.

The next step was to see how we could remove the weaknesses of standard impact star bit sockets and Torx socket sets by redesigning the impact socket to respond to the modes of failure. Our aim was not to make a stronger version of an existing design, we expected to make an innovative step in impact socket technology. What we ended up with was the best impact star bit socket set in the world today, and we have the test data to prove it!

How do impact bit sockets fail?

The modes of failure of impact bit sockets tell you a lot about where the highest loads are and where the weak points are in existing designs. By testing impact sockets to failure we identified three major issues with existing impact bit socket engineering that are responsible for almost all impact sockets breaking under repeated load.

- Design for manufacturing causing weakness at bit and socket interfaces

- Using alloys that are not durable enough for the stresses of impact driving

- Material construction which cannot transmit or absorb dynamic shock loads efficiently

Bit and socket interfaces are made weaker by an imprecise interference fit

A common construction method for impact bit sockets is to drive a slightly oversized hex end impact bit into a hex shaped receiver in the impact socket. This is an example of design for manufacturing, and is not good engineering. A high precision interference fit can be a good way to fit a bit into a socket.

The problem is that a low precision interference fit causes structural stress to the socket, especially where the sharp corners of the hex are driven in. When carrying out destructive testing on impact bit sockets, this is a common point of failure, with the socket fracturing at these points.

High quality alloys are needed to absorb impact driver stress loads

Impact driving puts very high stress loads on the bit socket, this is because the efficient transfer of those loads is how the impact driver is able to loosen highly torqued and even seized fasteners, and to deliver impact loads to tighten fasteners to required torque levels. You need to make impact bit sockets out of very hard, resilient materials to enable them to take the stress. Most impact sockets are made out of standard tool grade Chrome Molybdenum alloys, which are simply not strong enough.

What alloys did Poplock choose for our impact star bit socket set?

- high hardness HAT-08 alloy steel for the impact star bit (HRC 58-60)

- moderate hardness Cr-Mo 440 alloy for the impact bit socket (HRC 46-52)

Material construction needs to match impact driver dynamics

The final problem with most impact bit sockets is another material problem, either using single alloys to make a one-piece bit, to overcome the problem of fitting a bit into a socket, or using an extremely hard bit in a much softer socket. The dynamics of impact bit driving make it essential that you have a very hard tip to your impact bit, but a more resilient socket and bit shaft that can endure the repeated shock loadings. This is the reason for two-part impact bit sockets, but you need the right alloys to make it work.

What are 3 reasons to choose a Poplock impact star bit socket set?

There are three very good reasons to choose the Poplock impact star bit socket set instead of one of the other impact star bit socket sets on the market today. None of these reasons are about branding or marketing, they’re all about the well researched, carefully considered engineering and construction choices we have made that give you a better tool.

- Poplock uses a better choice of hardened alloys that match impact driver dynamics

- Revolutionary, patented, mushroom press fit solves the problems caused by an interference fit

- Exhaustive testing alongside other star bit sockets proves the Poplock design works the best

Better alloys that match impact driver dynamics

We improved on the alloys used in standard impact star bit sockets, meeting the need for high hardness for the star bit to maintain very positive engagement and prevent cam-out and fastener damage and moderate hardness with sufficient resilience in the impact bit socket to absorb repeated shock loads without dimensional deformation or brittle failure.

Mushroom press fit of impact bit into socket eliminates interference fit stresses

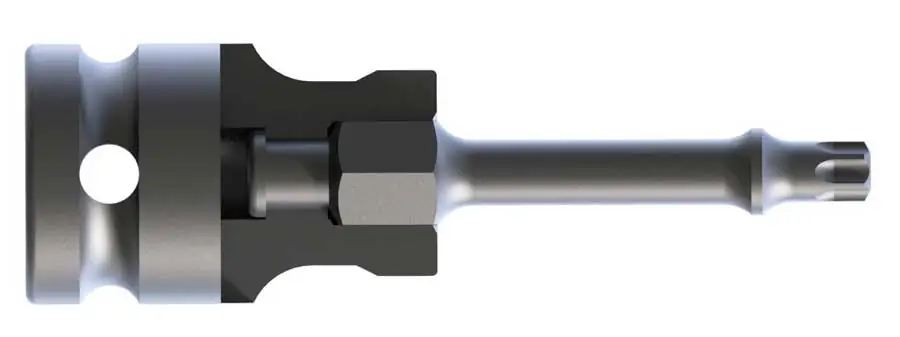

The most revolutionary part of the Poplock impact star bit driver design is the patented mushroom press fit of the impact bit into the impact socket. An extremely precise sliding fit (0.02mm tolerance) is used to maintain socket and bit integrity and responsiveness, with the bit held in place by a riveting, mushroom press, fit inside the socket. The socket is not stressed by the bit assembly.

The hot riveting press fit you can see in the video above has the added benefit of enabling selective heat treatment for grading the hardness of the bit to further reduce the impact of transition between the hard bit and softer socket when put under load. This gives a smoother response to the dynamic loads of impact driving, for vastly improved service life and more efficient operation.

We tested the Poplock design to destruction against our competitors

To verify the effectiveness of our patented design, and check our engineering assumptions were correct, we carried out extensive destructive testing of the Poplock impact star bit drivers against competing designs by well known brands. We are known for our rigorous testing protocols to ensure the highest quality, as you can see from our previous testing of our indexing pry bars, and we were just as happy to discover our impact star bit drivers were as good as we had hoped.

As part of our quality management programme for our impact bit driver sockets, we also created a specialized testing gauge to ensure that the Poplock impact star bit driver set conforms to Camcar Torx standards and is 100% cross-compatible with Torx fasteners to give our customers additional peace of mind. You can find more technical information on our impact star bit socket set on our product page, and the socket set is available online from the Poplock Amazon Store.