Indexing pry bars need to be tough to survive, so how do you work out how tough your indexing pry bar is, and what steps can you take when choosing an indexing pry bar to ensure it is tough enough for the intended use? From design features to construction details and the choices of materials used, let’s look at how you can identify a high quality, durable, indexing pry bar compared to a low quality version with a fraction of the strength.

How do we test the toughness of an indexing pry bar?

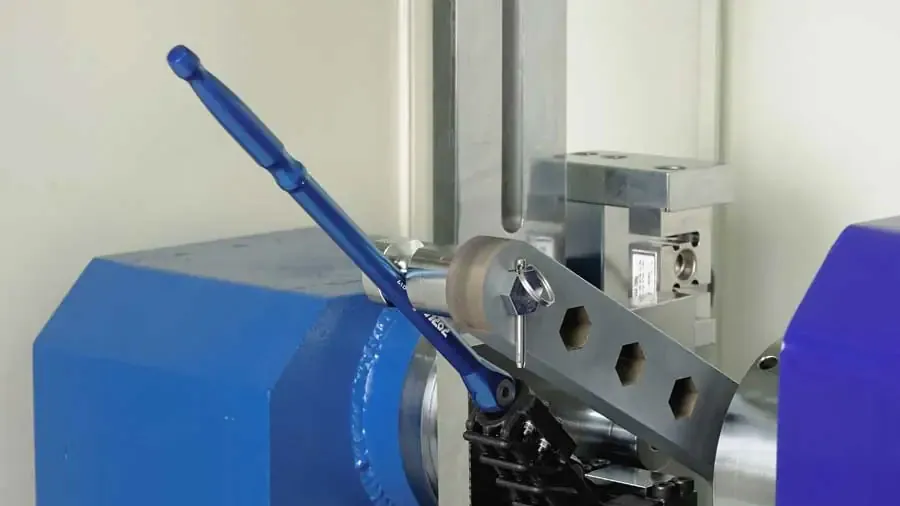

To test the toughness of indexing pry bars, we put our pry bars and competitor brands through repetitive stress cycles meeting or exceeding US ANSI standard ASME B.107.60-2004. This standard defines the expected characteristics of a pry bar being retailed in the US. The method used by the independent testing agency was to repeatedly apply 3000 in-lbs (339 Nm) of progressive force to the pry bar in a testing rig similar to the one shown in the video above.

The test was continued until the individual pry bar being tested failed, or, in the case of some of our Poplock pry bars, the engineers stopped the test when it became apparent the pry bar was not going to fail under these testing conditions. In the test reports we received photographs that showed the mode of failure of each pry bar. These are very useful as indicators of problems with the engineering and materials of the pry bars being tested.

What are the design features of high quality, tough, indexing pry bars?

It’s a lot more difficult to design and manufacture a high quality indexing pry bar than it is to make a cheap, unreliable one. People have issues with poor quality indexing pry bar mechanisms, which manufacturers need to address. Material quality and attention to engineering details are essential foundations for getting the design of an indexing pry bar right. A holistic approach to the functional design of a pry bar is an indicator of good design, as we will see.

What are 3 design details that indicate indexing pry bar quality?

- Some free play in the ratchet in the locked position

- A clean, fine edge to the pry bar head

- Some give and rebound in the pry bar shaft

Why should there be some free play in the ratchet of an indexing pry bar?

High quality indexing pry bar ratchets should have some movement in them even in the locked position. This may seem counterintuitive, surely you want the ratchet to lock solid in each position? Actually a ratchet that locks into place with no free play is poorly machined and is likely to freeze in position. A very small amount of free play is essential to enable the ratchet to operate, and should not reduce the strength of the indexing system in a well designed pry bar.

Why should the edge of the pry bar head have a fine profile?

The edge of the pry bar head in a rolling head pry bar should be very fine, not thick and chunky. There are good operational reasons for this – you need to be able to get the edge under the cam or component you need to pry, or between two surfaces without needing to pry them apart with another pry bar, which has a finer edge, just to make space. Low quality bars tend to have thicker edges.

Why do you want to feel some give in the pry bar shaft?

There should be some give and rebound in the shaft of the pry bar. This is essential to absorb shock loadings without failure. A completely rigid bar is likely made of cheap casting materials which have a hard crystalline structure. These will tend to fracture or shatter without warning, especially in places the casting is thinner – often around the ratcheting mechanism.

How do indexing pry bars fail?

When indexing pry bars fail, they tend to fail in specific and predictable ways that are directly related to how they are engineered. Let’s have a look at the most common modes of failure for indexing pry bars subjected to repetitive fatigue testing and see how they show the difference between a high quality well engineered pry bar and one made from substandard materials or with poor engineering design.

Fracturing of the ratchet casing & low ratchet quality

This is a common point of failure for bars that are not made from high quality alloys, or have poor engineering design of the ratchet casing, creating a weak point. The example above is a branded indexing pry bar, manufactured by an OEM supplier in China. The ratchet casing of this bar fractured after 6291 cycles at 3000 in-lbs / 339 Nm

This example from the same source failed after only 1739 cycles at the same intensity. You can see the extreme wear on the ratchet teeth, and the ratchet drum also shows rust corrosion. The corrosion was hidden behind the ratchet end caps, and the ratchet surround has fractured.

In the case of the telescopic indexing pry bar shown above, the ratchet drum teeth failed after 2154 cycles, making the pry bar useless. This example is a globally recognized brand which manufactures OEM indexing pry bars in China as well as other tools in their extensive catalog.

Ratchet ring failure

A common point of failure of low quality indexing pry bars is for the ring enclosing the ratchet to break open under loading. The shaft of the indexing pry bar should bend before anything breaks. The example above, from a different manufacturer, also has a fractured ratchet ring casing but there is less premature wear to the ratchet teeth, so it may have slightly better components than the previous example. This indexing pry bar failed after 8803 cycles at 3000 in-lbs / 339 Nm, and is manufactured in China for a major international brand.

After 6,700 cycles, this example from the same manufacturer was doing well until it suffered catastrophic failure of the ratchet ring. You can see that the ratchet ring is an obvious weak point in the design of these indexing wrenches as it has been reduced in thickness to fit inside the rolling head of the pry bar, which from an engineering perspective is illogical, as we can see when we look at a well engineered indexing pry bar.

How do we recognize a well engineered indexing pry bar?

The image above shows the condition of a Poplock indexing pry bar and the ratchet components after the same 3000 in-lbs / 339 Nm test, conducted until failure. The independent testing company stopped the test on the Poplock pry bar after 44,300 cycles without having been able to break the ratchet or ratchet ring.

- No ratchet failures, even after extended test cycles

- Integrity of the ratchet ring is maintained without visible wear

- No bending or distortion of the shaft or components

You can see some chipping to the edge of the rolling head as indicated in the photograph above. There was minor cosmetic damage to the shaft finish caused by the testing machine clamps and some minor wear to the ratchet wheels but no mechanical failures of the ratchet mechanism, shaft or ratchet ring.

A notable difference between the Poplock indexing pry bar design and the other examples given here, is that the ratchet ring is split around the ratchet with the hardened rolling head of the pry bar fitted inside it. This enables us to use a thicker, stronger section of a resilient material for the shaft of the pry bar and a harder, more resistant material for the rolling head without compromising on strength.

Poplock indexing pry bar sets combine durability and flexibility

You can see how Poplock engineers durable, reliable indexing pry bars. In repetitive fatigue testing of a range of branded indexing pry bars alongside Poplock designs, the Poplock designs outperformed every single other brand. The number of test cycles for Poplock designs was between 20,837 and 43,300, with no catastrophic failures. Four of the seven other brand examples failed catastrophically in fewer than 3,000 cycles, and the best performing of them all failed after 12,537 cycles.

- 8” & 12” single indexing pry bars

- 17” double indexing pry bar

- 17” single indexing nail puller

- Tough Cr-Mo alloy head and indexing gears

- Resilient Cr-V alloy handle

- Industrial hard Manganese Phosphate head surfacing

Poplock indexing pry bars are available as individual units or in flexible indexing pry bar sets that are suitable for a very wide range of prying tasks, big and small. You can be reassured that unlike our competitors our indexing pry bars are built to last, based on solid engineering design principles, and manufactured to excellent quality standards here in Taiwan. Check out our indexing pry bar set and indexing nail puller and find them on the Poplock Amazon store.